SHANDONG HOHN GROUP: DREDGING FLOATING HOSES AND PIPE AND FLOATS EXPERT SINCE 1988! DEDICATED IN OFFSHORE CONSTRUCTION;DREDGING;MARINE SERVICE.

Dredging projects are often classified into three categories: capital, that is, for new infrastructure, maintenance, or remedial (environmental) projects.

Coastal areas have always been a favourite place for people to settle. Living near the sea and other types of open water, such as rivers, estuaries and lakes, offers many benefits. These areas often have a more moderate and comfortable climate, as well as allow access to maritime food sources, and facilitate trade and transport.

The overall growth in the global population and the trend of migration towards coastal areas has led to a huge rise in the number of land reclamation projects. Industrial sites, residential areas, ports and airports are increasingly expanding in the direction of the water. The dredging process uses sand, clay or rock from the seabed to create new land elsewhere. Many land reclamation activities are combined with projects for deepening of ports and access channels, since the reuse of the dredged materials for adjacent jobs may reduce the total costs.

HOHN group own-patented self floating hoses is made of high quality and wear-resistant rubber, the outer cover has excellent abrasion resistance and UV protection.

The outside of the tube is wrapped with buoyancy material and covered with a protective layer.

HOHN floating dredging hoses are widely used with dredgers for silt or gravels conveyance.

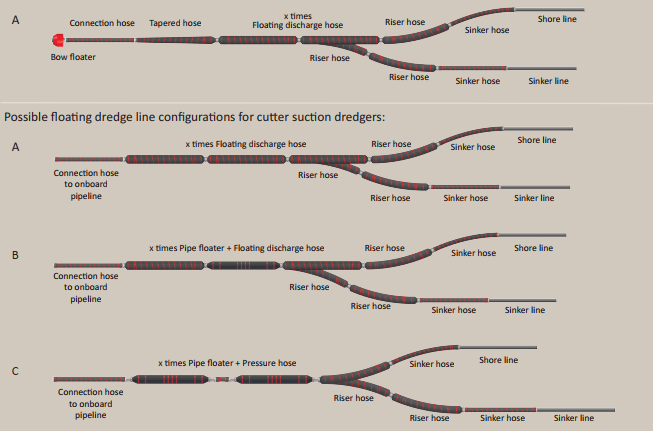

Floating hoses configurations can contain:

Floating discharge hoses; Pressure hoses; Tapered hoses; Connection hose; Riser hoses; Sinker hoses and Bow floater.

Possible floating dredge pipelines for Trailing Suction Hopper Dredger and Cutter Suction Dredgers please check below(Also applies to the Full armored rubber floating hoses dredge line )

HOHN GROUP Full armored rubber floating hoses advantage introduction:

HOHN Group Inner full armored rubber hoses for dredging: It is composed of metal cone pipe, rubber layers, steel wire, rubber outer coating and flanges. The structure type is that multiple cone pipes are nested in sequence. After being combined with the rubber layer, Multi-strand steel wires are tied and fastened together, and finally covered with a rubber outer coating.

In dredging works, when conveying solid materials with sharp angles, ordinary rubber self-floating hoses are easily damaged inside.

For the steel ring armored floating hoses, as the rubber and steel rings is not synchronized, it result in grooves.

HOHN Group Full armoured rubber floating hoses are equipped with wear-resisting metal cone sleeves through the rubber hoses, so the solid dredging sediments (like Coral reef, medium coarse sand, heavy stone etc) and rubber hoses do not contact and wear synchronously, so as to achieve the effects of wear-resisting, bending cushioning and wind wave resistance. It can bend more than 30 degrees. In the working conditions (Midium containing sand less than 30%) the buoyancy is above 25% of the hose outer diameter.

Flanges could be customized according to your requirements.

HOHN GROUP Full armored rubber floating hoses Specifications:

| ID mm | PCD mm | Hole Number | Hole ID | Length mm |

| 600.0 | 760 | 18 | 27 | 5800/11800 |

| 650.0 | 780 | 24 | 27 | 5800/11800 |

| 700.0 | 840 | 24 | 27 | 5800/11800 |

| 750.0 | 920 | 30 | 28 | 5800/11800 |

| 800.0 | 970 | 32 | 30 | 5800/11800 |

| 850.0 | 1020 | 24 | 32 | 5800/11800 |

| 900.0 | 1110 | 28 | 39 | 5800/11800 |

| 1000.0 | 1210 | 28 | 45 | 5800/11800 |

HOHN GROUP Full armored rubber floating hoses Specifications

HOHN Group full armored floating hoses makes the inner wall of rubber hose not exposed, and partial grooves after wearing wont happen.

Existing problems for steel ring armored floating hoses:

1 steel ring off as the boding strength is not enough between the ring and rubber

2 Resulting grooves

3 Deformation and blockage of the ring

Our Full Armoured Hoses Series produts are exclusively produced in the world and are incomparable with hoses products currently circulating in the dredging market, and have superior performance of Wear-resistant and durable.

It all depends on your dredging needs to choose common dredging floatinghoses or full armored floating hoses dredge line.

Welcome to visit HOHN Group official website for more details: www.floatinghosesllc.com