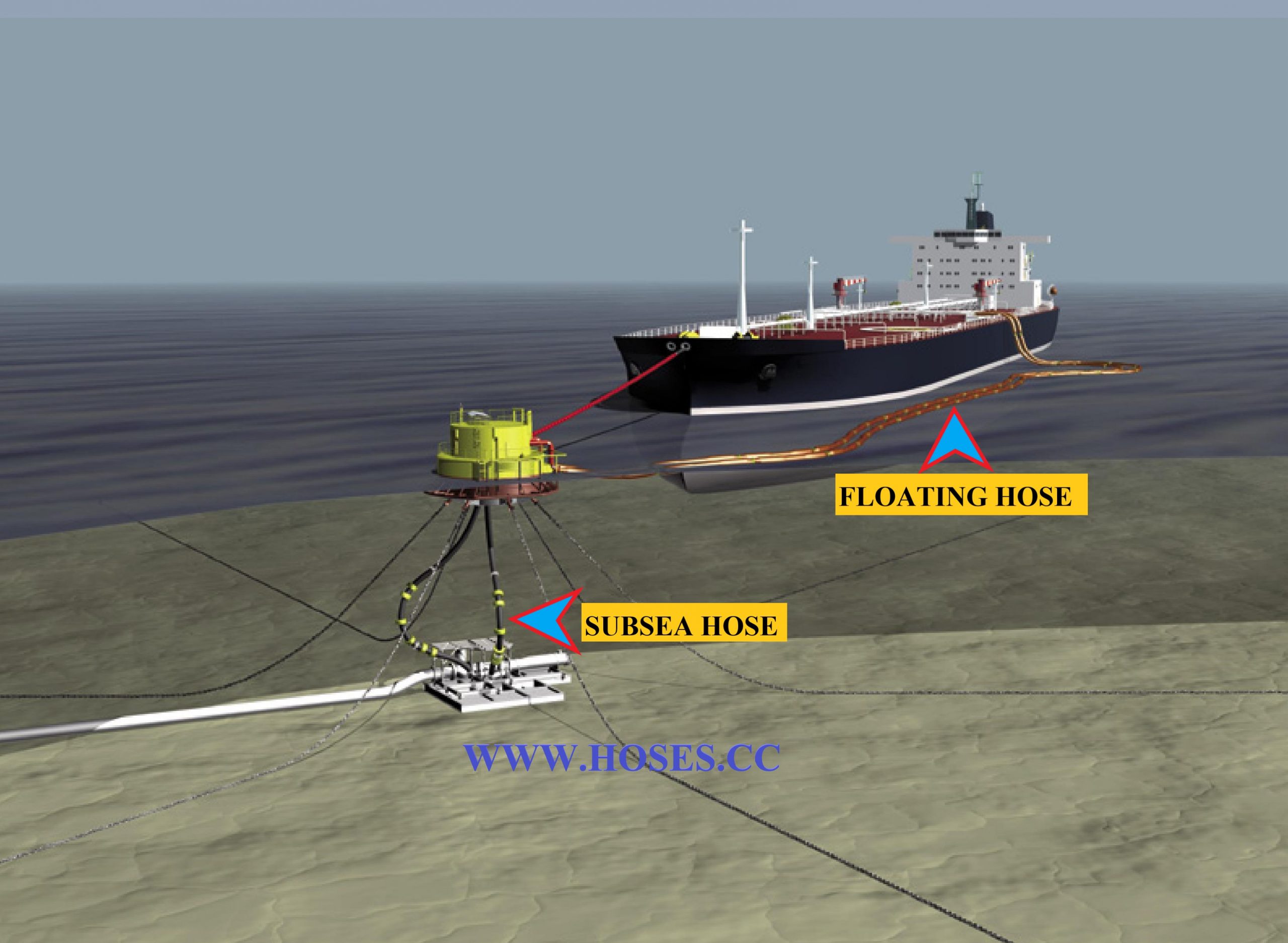

HOHN UNIQUE TECHNOLOGY:

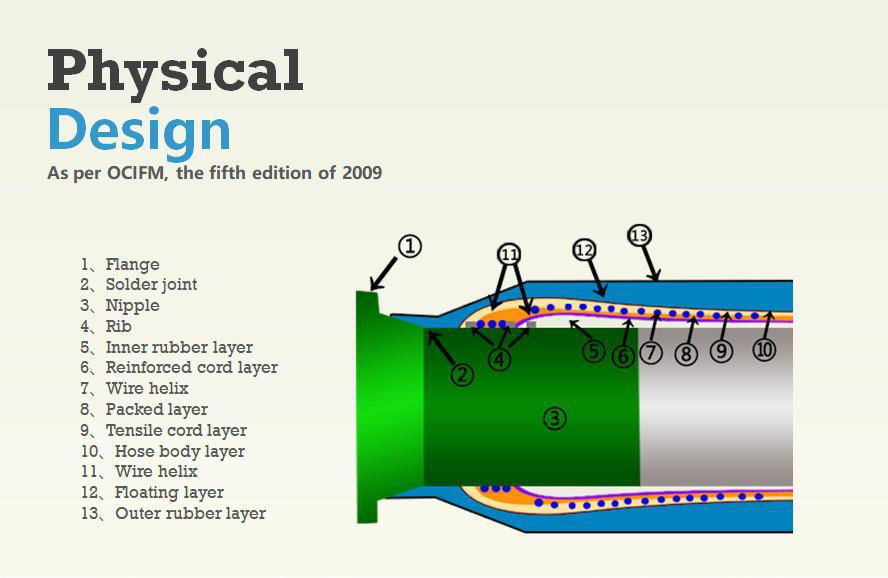

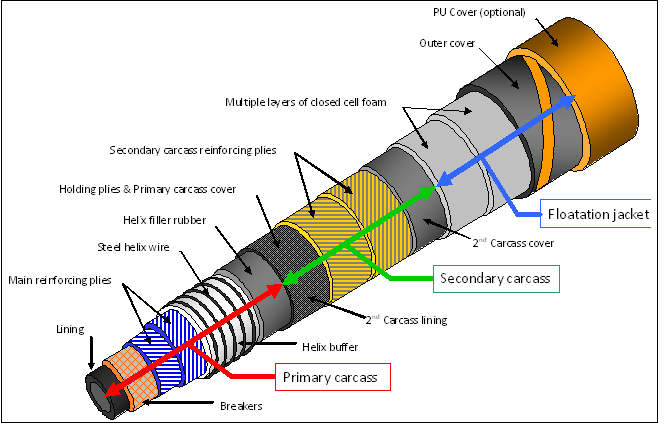

1: The production process of our company’s OCIMF 2009 Submarine and Floating hoses adopts the inner and outer rubber layer and the thermoforming extrusion technology to greatly improve the adhesive strength of the rubber layer.

2: The forming of the reinforcement layer is a 360° continuous forming technology of continuous cords (the advantage is that the outer diameter of both ends is reduced, and the pull-out force at the hose and nipple is improved). For example, the reinforcement layer of a 24 inch floating tube requires 40 layers The above cords are wound, so the method of other companies is to reserve a 500-length cord after each layer is formed, and then cut the second layer. In this way, the outer diameter of the two ends is equal to 80 multi-layers increased. Obviously our company has advanced production technology and unique technology in the world.

3: The vulcanization technology of the sealing layer outside the floating layer is a pressureless vulcanization method with a vulcanization temperature of 130°C, which has a beautiful appearance (also unique technology). And the production process is basically mechanized. Other companies can’t do it.

For more details about our OCIMF 2009 hose for FPSO,SPM,CALM etc pls contact: gq@hoses.cc